What are the factors associated with optical lens resolution?

An optical lens is an optical element made of transparent material and is an independently assembled part. It includes a lens barrel (including an aperture), a lens, a spacer, a stopper and other structures. The more mature technology of optical lens manufacturers is the single substrate coating process, that is, the use of glass, crystal, PC or resin and other materials, through the optical technology to make the lens substrate, and then use the coating process to coat the surface, with wear resistance, anti-fouling, anti-ultraviolet, anti-radiation, anti-blue, anti-glare and other functions. So what are the factors related to the resolution of the optical lens?

25

2024-06

Surface defects of optical components

Surface defects of optical components, often referred to as "surface finish" or "surface defects", are indicators that describe the number and size of pitting, scratches, and edges allowed on a polished surface. In the imaging optical system, the quality of the component surface directly determines the imaging performance of the system, in the field of strong laser and semiconductor applications, when the component surface quality is not good, it will lead to the situation that the optical system can not be used, therefore, it is very necessary to clarify the definition and determination method of the component surface defect. However, in practice, there are many standards for determining surface defects, and the definitions of each standard are not uniform, which brings some confusion to the actual work of optical practitioners. In view of this situation, this paper from the 1185-1974 old national standard, the United States military standard and the new national standard with reference to ISO 10110 three standards, introduces their specific content, as well as the approximate correspondence between each other, so as to help you in the actual work can better identify and control the surface defect index of the component.

25

2024-06

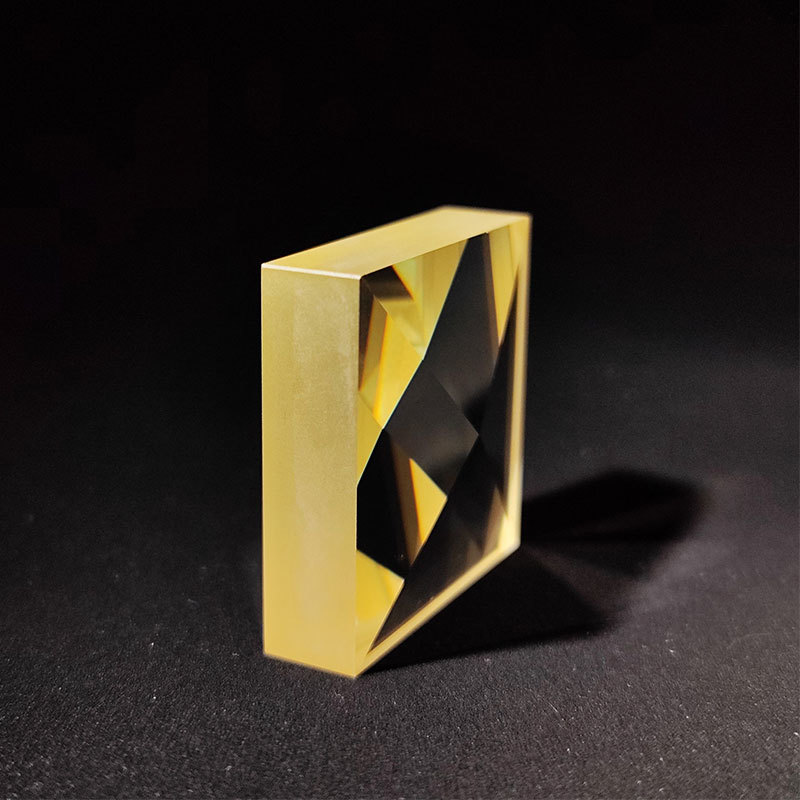

Laser lens direct good or good reflection?

Laser lenses are generally divided into two categories, which are commonly known as reflective and direct laser lenses. The reflective type uses a blue laser head to hit the laser on the high beam led phosphor to emit light, which enhances the high beam. There is a direct laser lens, but the so-called direct laser lens laser module also needs to be divided into two categories, one is a transmissive laser head, and the other is a reflective laser head. Transmission type laser head, is the laser emits white light through the luminous body, the volume is small, but the white laser head spot has yellow halo. Reflective laser head, is the laser head light to the molybdenum reflective lens, the laser is reflected to the phosphor, the relative volume is large, but the spot is perfect. So the laser lens direct good or reflection good? The following small series to introduce to you.

25

2024-06